Lee Van Cauwenberghe - 3D Printer of the Month

Tell us about yourself and your experience with 3D printing

I have been a junior high teacher for 27 years so I've seen a lot of change in technology over that time. I've gone from using the good old Commodore 64 in my class up to what we have as PC's today. I got into 3D printing only a few years ago. I thought the applications and possibilities of what it could do in our education system endless. After just starting to familiarize myself with how things work, and I am still a novice, I got into creating things and designing this myself and trying to get my students involved with it as well.

What 3D printer(s) do you own?

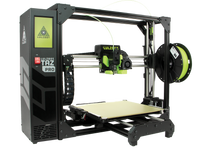

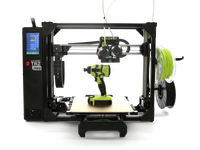

The 3D printers we own at school are a TAZ 6 and I use a Lulzbot Mini and I absolutely love it.. It was everything as advertised as far as ease of use and setup right out ofthe box. I was printing in less than 30 minutes after unboxing it.

What design software do you use most often? Why choose this over other software?

What is your favorite filament to print with? What do you like about it?

I have used PLA 95% of the time. It is easy to work with and I've never had an issue with it. I have read that it is a good filament for beginners to experiment with. I just recently for the first time used wood as a filament and the results were incredible. It worked much better than I anticipated.

Are there any additional tools, resources, or software you use often with your 3D printing projects?

Is there anything you know now that you wish you knew when you first started 3D printing?

YES. Spend a few extra dollars and get yourself a GOOD machine. This Lulzbot Mini cost a little more but it is just fabulous. I can't say enough good things about it. I bought a DIY kit that cost less. I seriously put HOURS into meticulously building it and I thought it was perfect and for all the time and effort the machine never produced a single print. I was very disappointed..........I can send you the name of it if you like.

What common mistakes did you make when first getting started or that you see new users make?

What are the biggest challenges you face with 3D printing?

What applications do you use 3D printing for? Why did you choose 3D printing over a different tool or process?

Two other things I've used my printer for......I use spinners as part of my curriculum to teach probability. The spinners cost $20 for three of them and when the arrow spinner breaks you can't get a replacement. So I designed new arrows for the spinners and most recently a whole new spinner myself. I can now print 3 of them for under $5. I have plans to contact the company to see if they would like to purchase my replacement spinner arrows as part of their inventory. I'm hoping that may help with the filament budget.

I also just recently personally purchased a new laptop. It has an SSD with no hard drive. I wanted a hard drive for more storage and the unit did not come with a hard drive caddy. I found one online but low and behold they would not ship it to Canada. I tried a few places and to purchase and ship this tiny caddy, they wanted $50+ for everything. I was not going to pay that much......so I turned to my 3D printer. I designed a caddy for the hard drive and it took quite a few tries to get it just right but I have a design that is perfect for the application. I just thought, maybe I'm not the only one with that problem. So I advertised the caddy online, and to date, I have sold at least 100 of them, not for $50, but for $8.49 including shipping. People have raved about the design and the cost. So that is what is supplementing my filament/repair budget right now. I'd love to get more exposure for it because I think I could sell a lot more of them.