Have Questions?

-

Only Top Quality Products

Only products from trusted brands

-

Personalized Services

We respond within 24 hours

-

Secure Payment

100% SSL Secure Payments

-

Canadawide Shipping

Free shipping on orders $99.99+

3DXTech CarbonX™ Carbon Fiber Nylon 3rd Generation Filament

Product Alert: This material is highly abrasive and tool heads and components require hardened-steel components. Find a list of compatible printers an upgrades below:

Ultimaker 3D Printer - Ultimaker S3 and Ultimaker S5 with CC Red Print Core

Lulzbot 3D Printers - Lulzbot Mini 2 or Taz 6 with HE, HS or HS+ tool heads. Lulzbot TAZ Workhorse and Lulzbot TAZ Pro 3D Printers come stock with hardened steel components.

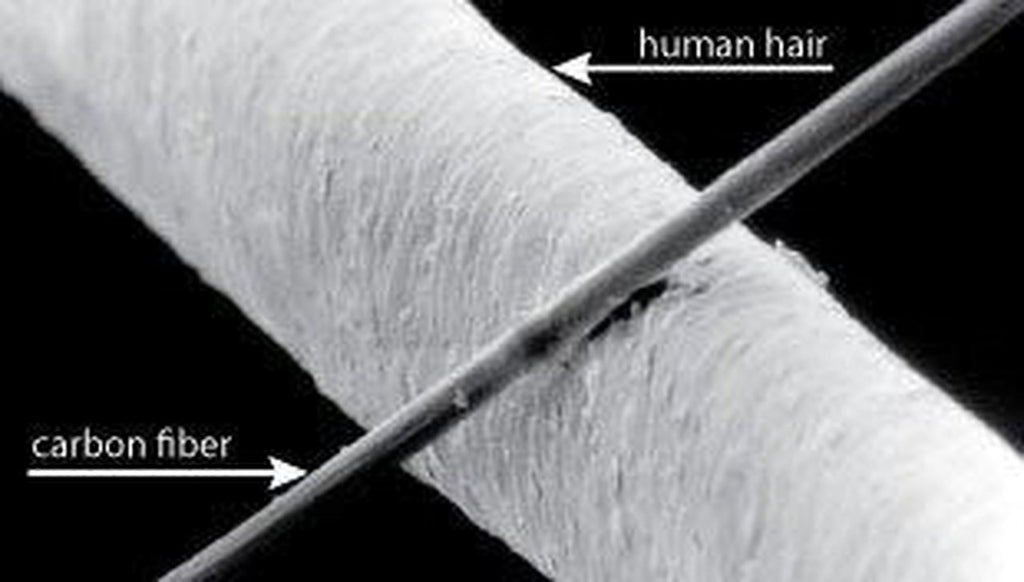

Gen 3 CarbonX™ CF-Nylon Filament is an advanced semi-aromatic polyamide copolymer reinforced with high-modulus carbon fiber. This filament is ideal for anyone that desires a structural component with high modulus, improved chemical and thermal resistance, excellent surface quality, and ease of printing. Tired of nylon that warps? This is the answer you've been looking for. Excellent dimensional stability comes from the carbon fiber and the semi-aromatic nylon.

|

|

High-Performance + High Temp Resistance: Gen3 CarbonX™ CF-Nylon is a PA6 copolymer made using high-modulus carbon fiber and state-of-the-art compounding and extrusion technology. Gen3 has higher HDT than our previous grades (147°C at .45MPa) allowing for expanded use in higher-temp applications.

Open Source: You do not need to purchase a special printer for CarbonX™ CF-Nylon. Our CF Nylon (Gen 3) is suitable for use in practically any desktop 3D Printer that has a heated bed.

Chemical Resistance Chart

Recommended Print Conditions:

- Extruder: 240-270°C. CarbonX™ CFR Nylon exhibits improved layer bonding at higher temperatures.

- Bed Temp: 80 - 100°C

- Bed Prep: Polyimide Tape, Clean glass with ABS/Acetone Slurry

- Hardened Nozzle: 0.4mm or larger.

- Layer Height: Ideal layer height is 60% of nozzle diameter. We do not recommend printing layers below 0.25mm with carbon fiber grades. Lower than 0.25mm may create too much back pressure in the hot end and result in poor feeding, jams, drive gear clicking, and eating a notch into the filament.

- Drying Instructions: It is very important to keep this material dry and prevent moisture absorption. Dry this material at a max temperature of 90 degrees C for 4 hours. See our filament dryers here to help with this.