Greg Walsh (MUN Med 3D) - 3D Printer of the Month

Tell us about yourself and your experience with 3D printing

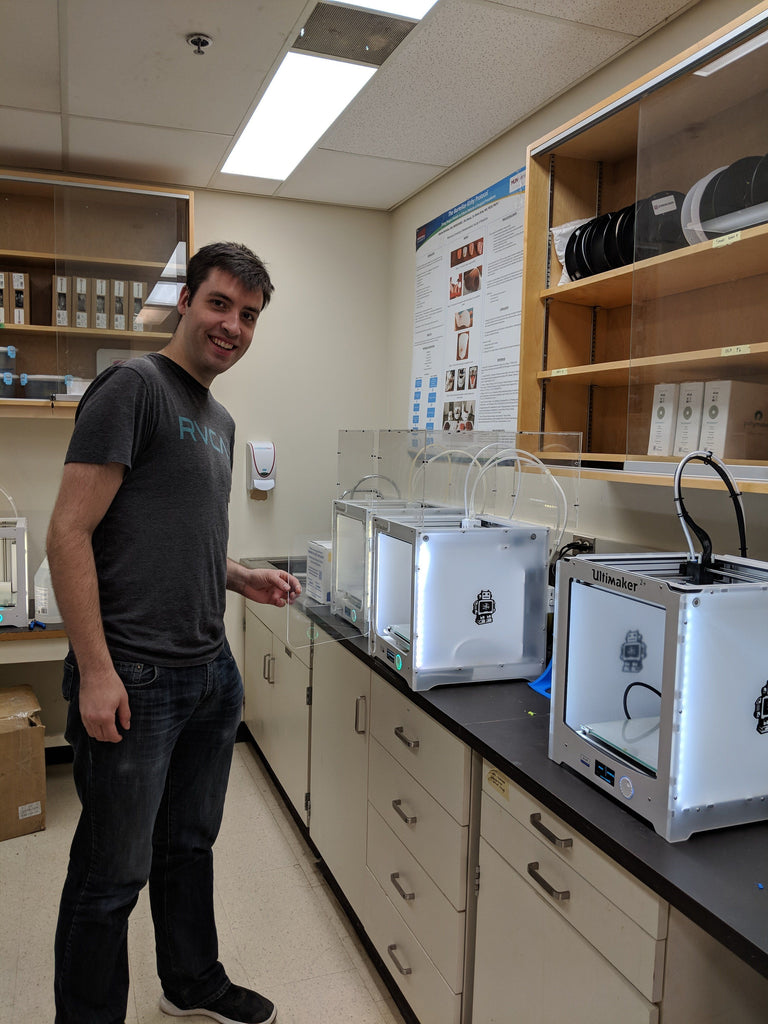

Print being done on Ultimaker 3 printer

What 3D printer(s) do you own?

Currently, we have a bank of five Ultimaker 3s, one Ultimaker 2, a Lulzbot Taz 6, one Form 2, one Markforged Mark Two Pro, one Markforged Onyx Pro, and a Stratasys Objet 260 Connex 3. Additionally, we currently have six satellite sites in hospitals around the Atlantic region, each equipped with an Ultimaker 3, with another two sites possibly on the way. We are also looking at expanding our main laboratory capabilities before the end of the year.

Autodesk Fusion 360 is currently our primary CAD software.

Foot print used for education. Source: www.munmed3dnetwork.ca

What is your favorite filament to print with? What do you like about it?

Currently PLA since it allows us to rapid prototype at a low cost, with fairly good results, though we have been increasing our PETG use recently.

Are there any additional tools, resources, or software you use often with your 3D printing projects?

3DExport is a great resource for paid-license models, and Autodesk Fusion 360 is currently our primary CAD software.

Pelvis bone print used for education. Source: www.munmed3dnetwork.ca

Is there anything you know now that you wish you knew when you first started 3D printing?

Like us at the lab, before we had exposure to the technology, I believe a lot of people think 3D printing is some modern-day magic - press a button and an object comes out, the same as using a 2D laser printer. They don't realize the amount of file tuning, printer tuning, maintenance work, and material care that 3D printing requires. It isn't a plug-and-play technology quite yet, and I wish I was a little better prepared for what I was getting myself into.

What common mistakes did you make when first getting started or that you see new users make?

What are the biggest challenges you face with 3D printing?

Knee injection model used for simulation training. Source: www.munmed3dnetwork.ca

What applications do you use 3D printing for? Why did you choose 3D printing over a different tool or process?

We see 3D printing as a low-cost point-of-use manufacturing for rural healthcare sites to improve simulation training. The central lab develops medical task trainers and simulators, and our satellite sites allow rural hospitals to reproduce them at a fraction of the cost they would be spending to buy comparable units at market prices. This allows regions to access training tools they normally wouldn't have the budget to obtain.

Where can people can learn more about you and see more of your work?