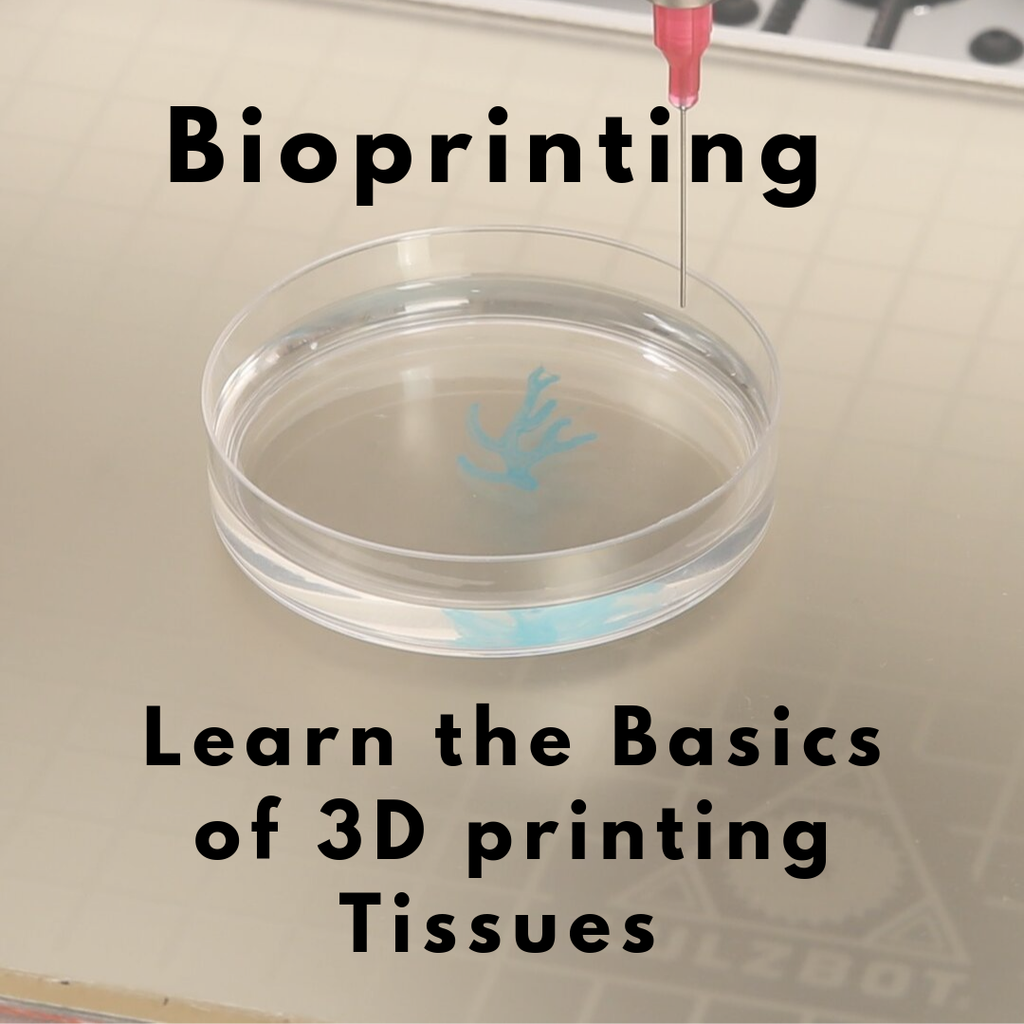

Learn the Basics of 3D Bioprinting & 3D Printing Tissues

3D Bioprinting and 3D Printing Tissues

Healthcare has always been at the forefront of using 3D printing technology and experimenting on it to apply the technology in multiple revolutionary ways. 3D printing, now, is not only used for printing out pre-surgical models and prosthetics but also to 3D print complex implantable tissues and organs through a method which is appropriately known as 3D bioprinting.

Bioprinting is the branch of 3D printing which prints three-dimensional tissues and organs from specially formulated bioinks. The bioinks are made from a mixture of chemicals, stem-cells, or living cells. The actual printing is carried out in a gel-like base made from collagen, gelatin, hyaluronan, silk, alginate or nanocellulose.

Bioprinting is not only a need of the hour but the only way to transform the way healthcare is delivered to millions and billions of people. This is the beginning of a revolution in the healthcare sector and the future as envisaged by many visionaries.

UNDERSTANDING THE BIOPRINTING PROCESS

Process of Bioprinting/Courtesy: FluidForm

The process of bioprinting is fairly similar to how a regular 3D printer operates apart from a few distinct differentiations which are noted below. Read on to know the steps involved in bioprinting:

- Patient Data Imaging: Similar to all the 3D printing processes, the bioprinting process also starts with a digital file. The patient data is pulled from MRI and CT scans for further processing in CAD software.

- 3D Modelling: The patient data is then imported in medically compatible CAD software to create a 3D CAD model of the implant. The model is adjusted for finer features along with defining the slicing & layer settings.

- Material/Bioinks: One of the most critical steps and the one which can directly impact the patient in bioprinting is the production of the material or bioink. Stem cells from the patient are used to formulate the bioink to be used for the bioprinting.

Cartridges loaded with Bioinks/Courtesy: Cellink

- Pre-Bioprinting: The bioink so formed, is then loaded into the printing cartridges as shown in the above image and final settings are rechecked in the software and the bioprinter is recalibrated so that any possible occurrence of failure is eliminated.

- Bioprinting: As per the pre-set settings the Bioprinter starts printing the model in a well-defined pattern inside a gel-like watery substance, called as a hydrogel. This gel supports the structure.

Bioprinting is carried out by a needle-deposition system/Courtesy: FluidForm

As the layer-by-layer process continues the initial layers solidify assisted by external UV light stimulation/exposure. The successive layers are deposited on top of the previously solidified layers and thus the complete object is able to hold its shape.

- Curing Stage: Once the printing completes the bioprinted structure is left in the gel for maturation and growth before being removed. The appropriate curing mechanism is employed ranging from time, UV light exposure, temperature, chemicals, etc., to allow the part to cure and mature.

Curing stage/Courtesy: FluidForm

And after sufficient maturation, the printed structure is separated from the hydrogel for appropriate usage in experiments or implants. In most cases, the support material is melted away to release the bioprinted part easily.

WHERE WE STAND TODAY?

Bioprinting an ear specimen/Courtesy: Cellink

Bioprinting, as mentioned earlier, is used by researchers to print tissues and organs. Although the prospects are very bright, it is still a distant reality when we will actually be able to implant fully bioprinted organs like livers kidneys and even heart.

But the technology is taking huge strides towards the lofty aim. With numerous recent developments instilling faith in the early arrival of the final destination, bioprinter manufacturers as well are putting their best foot forward to develop printing systems which will help augment the capabilities of the healthcare scientists in their research.

Even though the scientists are capable of carrying out such complex research initiatives, they will have to be equally well supported by the necessary equipment’s and bioprinting systems which will reliably print and support their research.

The bioprinting systems are complex machines capable of printing out living cells from bioinks. The revolution envisaged in healthcare will only be supplemented with the help of efficient bioprinting systems.

We will take a look at one such new bioprinting system developed by LulzBot - the LulzBot FRESH Bioprinter, in collaboration with FluidForm. This revolutionary system will offer new bioprinting solutions to researchers across the globe.

LULZBOT FRESH BIOPRINTER

LulzBot FRESH bioprinter/Courtesy: LulzBot

Aleph Objects Inc., the manufacturer of LulzBot 3D Printers, recently announced a collaboration with FluidForm Inc., an innovator in 3D bioprinting, to combine their expertise to offer new bioprinting solutions.

FluidForm’s FRESH printing technique, developed in Carnegie Mellon University’s Regenerative Biomaterials and Therapeutics Group, enables 3D printing of bioinks and other soft materials. It harnesses the power of non-newtonian gels to allow movement through a material like it’s a liquid while supporting deposited material like it’s solid.

The new LulzBot FRESH (or Freeform Reversible Embedding of Suspended Hydrogels) bioprinter will be a handy system for scientists to fuel their research and study bioprinting. The LulzBot Bio is also seen to be a revolutionary printer which will have applications across a broad spectrum of industries including pharmaceuticals, regenerative medicine, drug screening, food and other animal products, cell-based biosensors, and testing of cosmetics and other health care goods.

FRESH 3D BIOPRINTING WITH LIFESUPPORT™

FRESH 3D bioprinting is performed by extruding bioinks and other materials within the hydrated, compacted LifeSupport support material, which is specially formulated to prevent constructs from collapsing and deforming while printing. A wide range of polymer crosslinking chemistries and gelation mechanisms are supported within LifeSupport by the incorporation of ions, enzymes, pH buffers and more into the support material during the rehydration process.

LifeSupport allows for FRESH 3D bioprinting of soft hydrogel bioinks in complex geometries without the need for sacrificial support inks (e.g., Pluronic® F-127, polycaprolactone, gelatin) or ink modifiers to increase mechanical stability (e.g., gelatin methacrylate, cellulose, alginate).

LifeSupport can be rehydrated in a range of buffers and cell culture media to support multiple cell types and specific bioinks. LifeSupport can also be rehydrated to support the cross-linking and/or gelation of multiple types of bioinks within the same support material.

Bioinks that can be printed include collagen, alginate, fibrin, decellularized extracellular matrix, methacrylated gelatin, methacrylated hyaluronic acid, and more. The specific bioinks that can be printed will also depend on the hardware capabilities of the 3D bio-printer being used.

We now take a look at some of the notable developments and the implications of how the new LulzBot FRESH bioprinter will fuel the research in bioprinting.

Five Important Areas of Application

While we see the strengths of the FRESH bioprinter, we will see the potential of FluidForm’s approach to revolutionizing five important areas of application.

Medical Applications

Trileaflet heart valve FRESH printed using collagen/Courtesy: FluidForm

The bioprinter has major applications in the medical field where it can help in the manufacturing of heart valves, other customized medical devices and ultimately scaffolds and engineered tissues for regenerative medicine applications.

Surgical Models

Currently the surgical models are mostly printed on FDM printers but these are usually the bigger organs of the body like bones, heart, liver, kidney, etc. but complex internal tissues and organs are also required for pre-surgical training to surgeons and these parts should be as life-like as possible so that the surgery can be accurately pre-planned and practiced.

Such anatomical models can be bioprinted using the new bioprinter.

Light-weighting

FRESH bioprinter can be helpful in 3D printing with fiber-reinforced materials commonly used in the aerospace and automotive industries, which can add strength to components without increasing weight.

Wearable Sensors

Wearable sensors are the new-age applications which can generate a deeper level of data for sports performance, lifestyle, and medical monitoring applications. Such customizable embedded sensors are a promising application in the coming years.

Mass Customization Manufacturing

Earbuds are a great example where mass customization is being applied to good use. Earbuds are customized for ear set of ears on a personal level. Such applications like eyeglass contours, handle, and control surfaces to provide individual customization with increased comfort, performance, and fatigue resistance will be prominent applications for FRESH bioprinter.

We now take a look at some of the notable developments and the implications of how the new LulzBot FRESH bioprinter will fuel the research in bioprinting.

NOTABLE DEVELOPMENTS IN BIOPRINTING

3D Bioprinting Hair Follicle

L’ORÉAL is researching on 3D printing of hair follicle/Courtesy: L’ORÉAL

L’ORÉAL has been one of the earliest beauty brands to commit to tissue engineering and has decades of expertise in the understanding of hair biology. A few years ago it started a new research and innovation project to bioprint a hair follicle - the small organ that produces hair, through a bioprinter.

According to Jérémie Soeur Head of Cellular and Tissue Engineering Group, “Dermatologists will be able to use a stock of cells to repair skin damaged by wounds or burns in a fast, effective way.”

Bioprinted Human Cornea

Scientists from Newcastle University have bioprinted a human cornea/Courtesy: Newcastle University

A team of scientists from Newcastle University successfully bioprinted the world’s first human cornea paving the way for a world free of blindness. The scientists can now create a bio-ink by mixing human corneal stromal cells from a healthy donor cornea together with alginate and collagen that can be bioprinted.

In addition to just bioprinting a cornea, the team also demonstrated the capabilities of printing unique patient-specific corneas. In short, the corneas of the coming future will be customized in the exact shape and size thus making the process more user-friendly.

This revolutionary research can be driven by a reliable system like LulzBot FRESH bioprinter and can impact the lives of millions of blind people and give them a chance to see the world.

3D Bioprinted Human Heart

World’s first bioprinted human heart/Courtesy: Getty Images

A team of Israeli scientists recently bioprinted a replica of a human heart with tissues and vessels. It was the first time when an entire heart replete with cells, blood vessels, ventricles, and chambers was bioprinted. But apart from the challenge of printing a human heart, the next and a ‘more’ important challenge is that the patient body should not reject the transplant, and so it is important to print the heart with living cells taken from the patient itself.

The researchers will now teach the bioprinted heart to behave like a real heart. The cells of the printed heart are able to contract but are not capable of pumping blood. This will be the first step. These hearts will then be transplanted in animal models by the next year.

Such sort of research takes years and hundreds of smaller experiments to be successful. These experiments can be significantly boosted by the power of the equipment these scientists possess. A fast, reliable and powerful bioprinter can augment such research and considerably cut down the research timeline.

3D Bioprinting human skin with natural pigmentation

Courtesy: L’Oreal

Skin grafting is an old surgical procedure to replace the damaged skin of a patient with the patient’s own skin cut out from a different body part. But this has its limitations. While the surgery is the first challenge, the main hurdle is the mismatch of the skin color at the site of the skin replacement.

This is a visible challenge which scientists now seem to have cracked. Researchers have developed a way that can make bioprinting of skin possible with the naturally occurring pigmentation.

The process can be truly revolutionary because it can bioprint skin closely resembling the native skin. In their study, published in Biofabrication, researchers used different types of skin cells – melanocytes, keratinocytes, and fibroblasts and used 3D bioprinting to control the distribution of melanocytes using a two-step drop-on-demand bioprinting strategy.

LulzBot FRESH bioprinter is capable of rapidly printing out such experiments and can deliver reliable results from its bioprinting system.

LulzBot & FluidForm’s novel platform of Freeform Reversible Embedding of Suspended Hydrogels (FRESH) 3D printing enables fabrication of soft, biological scaffolds for applications in tissue engineering and regenerative medicine.

Learn more about the LulzBot Bio

Learn how 3D printing is used in medicine