Tips and tricks for succesful 3D printing with PVA filament

Here are our top tips and tricks for 3D printing with PVA filament

PVA filaments allow you to print complex shapes and geometries that would otherwise be impossible thanks to dual extrusion and the way it dissolves in water. This leaves you with a very smooth and clean print compared to printing supports with single extrusion. So PVA can be a fantastic tool for printing these complex shapes and geometries. It can also be tricky at times because of it's unique composition that makes it so useful. That is why we compiled a few of our top tips and tricks to help you have successful prints with PVA!

You can learn more about PVA material from this video. It is made for Ultimaker printers but the general information about PVA does apply to other printers as well.

Here are our tips for successful 3D printing with PVA filament:

1) Always store the material away from moisture when not in use. PVA is doing it's job by dissolving when it is exposed to water. Unfortunately, it doesn't know the difference between the moisture in the air and water that you leave it in overnight to dissolve. This is why it is so important to store this away from moisture, away from sunlight, and in a dry and cool place. An easy and low cost option is simply using a sealed zip-lock bag with desiccant. A better option is getting a large container, one with a ruber seal to ensure it is air tight, and some re-usable desiccant. The re-usable desiccant allows you to bake out the moisture once it has become saturated. The small desiccant packs that come with spools can also be used but these will eventually become saturated and render them useless.

Additional resource: How to properly store your filaments.

2) When printing with a brim, always make the brim out of PVA instead of the model material. PVA with adhere better to itself than to other materials. That is why if you are printing a model that requires supports while using a brim, your best option is the make the brim out of the PVA.

See our video on how to change your brim material to PVA below:

3) Cleaning out your nozzle or hot end regularly. PVA has a tendency to ooze and carbonize easier than other filaments. For this reason, it can lead to nozzle clogs and jams more frequently than other materials. We suggest performing regular cleaning on the nozzle/print core you are using for PVA. Here are some additional steps for cleaning your hot end/print core with various printers below:

- For the Ultimaker print cores, we recommend cleaning out your BB print core at least once ever three months. You can find a detailed guide for how to do that here.

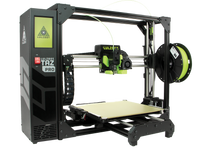

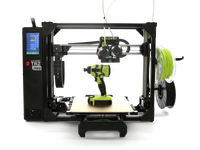

- For Lulzbot 3D printers when printing with the Dual Extruder V3, to clean out your hotend of any filament residue we would suggest doing some cold pulls using Nylon filament (Nylon tends to stick better than other filaments so it works well for this process.) When working with the V3 Dual Extruder to do cold pulls you will want to remove the idler tension screw completely so you can flip the idler open and get better access down through the hotend, then the steps would be the same as on the stock toolhead.

4) Speed up dissolving time. Typical time to fully dissolve PVA would be between 12-18 hours. This will vary depending on the brand of PVA you are using. There are a number of ways you can reduce the amount of time it takes to fully dissolve your PVA supports. We will cover a few of those below:

- Manually take off as much material as possible before placing in water. There will likely be some larger pieces that you can break off with pliers before placing your print in water. Be careful not to damage your model when breaking away the PVA support structure.

- Heat the water - Maintaining higher than room temperature in the water will help speed up the dissolving process. Be sure not to heat this to too high of temperature as it can begin to effect low melting point materials like PLA at even 40C. This can be done with a heater or changing out the water once it cools to warmer water.

- Agitate the water - Keeping the water moving will also aid in speeding up the dissolving process. This can be done with a pump or an ultrasonic tank.