3D Printing in Product Design

How is 3D printing used in product design?

At Print Your Mind we hope to keep opening your mind about the far-spread potential of 3D printing. Here we go beyond the idea of 3D printing for creating nice-to-haves but look at the true business potential this radical new way of manufacturing opens up by means of seven examples.

3D-Powered Prototyping

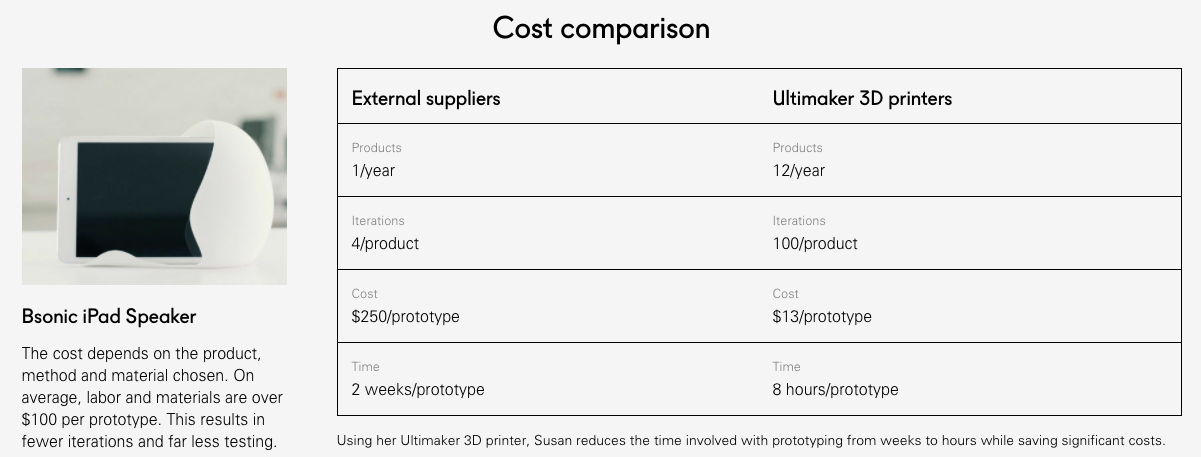

In 2013, Susan Taing founded Bhold, a design house that uses desktop 3D printers to create smart, minimalist accessories, all rapidly prototyped and tested by real users worldwide.

"When I first launched Bhold, if I had gone the traditional route I would have needed over a year for just one product, but with 3D printing I was able to launch with not one but four ready-for-market, thoroughly tested products in just three months."

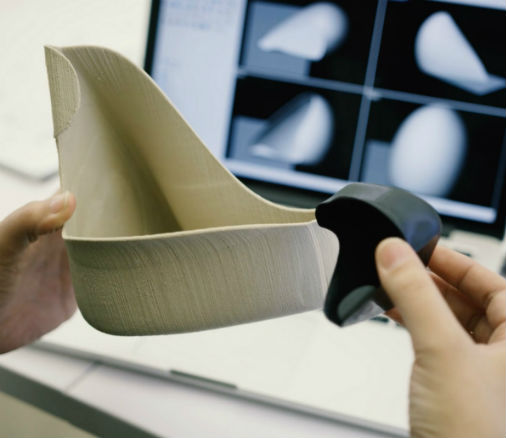

Tailored Footwear

Where once bespoke business models implied extraordinary craftsmanship, extended customer interactions and long supply times, 3D printing set up with online marketing and sales platforms makes it possible to bring back the value of tailored high quality products. Where high wearing comfort is a crucial selling point, 3D printing can step in to offer simple solutions such as a variable shaped arch-shaped inlay piece, sole shape, cushioning or patterning. Fashion designer Julian Hakes has been using Ultimaker machines to rapidly create prototypes and high quality test models before scaling up towards mass production. The Lulzbot TAZ Pro that our store carries even lets you print a full-size sneaker combining solid and flexible material with its dual head setup.

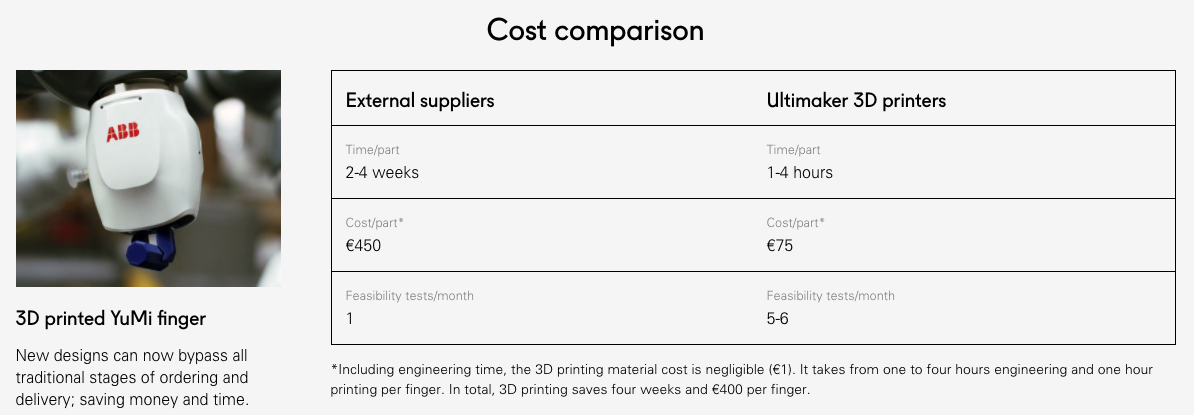

Lightweight Bio-Aesthetics

There are markets in which a progressive design can create a match between a customer and his or her product. In industries such as automotive, racing bikes and furniture, a future-forward feel provided by 3D printed parts where they are sensibly implemented can not only improve functionality but also create a higher affection for the product’s owner which ultimately leads to higher sales. Even if external service bureaus are employed for creating these complex parts for commercialization, creating prototypes on your desktop 3D printer can greatly speed up your development times by shortening iteration times and the number of high fidelity prototypes you need. ABB Robotics, for example, makes good use of the design flexibility 3D printing offers to optimize robot parts. They report to, in the long run, save € 100,000 for each Ultimaker they purchase.

Make-It-Yourself Models

A company can decide to empower 3D printer owners with the capability to create their own products or product parts, in the material and color of choice, with all design files provided by the company. Since digital files can and will never be able to be fully protected, sales volumes can be ensured by having the company provide a number of parts as a kit, unobtainable through other channels, and include the price for the 3D printed parts.

The Dutch startup Print+ is such a company and has run a sold out Kickstarter campaign marketing their 3D printed headphone kits. They offer several variations of the 3D printable parts that you can print on your desktop machine.

Do you want to receive other helpful articles like this one? Sign up for our newsletter today! We hate spam and you can unsubscribe at any time.

Modding and Replacement

With the arising of 3D printing as a mainstream means to manufacture, the notions of product and prototype intertwine and business can be set up to gain a customer base that helps evolving the products. Where trust is more important than ever for modern customers, them becoming an integral part of a company and actively contributing to product development cycles can prove to be of great benefit.

Bhold, a small creative agency, has a global product testing community that prints and evaluates their consumer products before they are being mass-produced. This allows them to develop up to 12 products every year as compared to the one or two products they would be able to bring to market following regular product development processes. Others are using 3D printed parts to modify one-wheels, furniture, 3D printers or 3D scanning and repairing home goods.

Design Customization

Factories were once the giant inaccessible monoliths, and only the privileged had the opportunity to have a peek inside let alone influence the products created there. Large fashion and jewelry houses on occasion allowed the select few to have their piece customized, but now this process is becoming democratized through 3D printing. Large companies such as Chanel and Pandora have for years been focused on creating customized products and we are seeing a slow uprise of startups that act as a touchpoint regarding the customization process between the corporation and the end customer. Having digital technologies as the middleman between a 3D printer and the 3D modeling process to create personalized items empowers people’s creativity and adds value to employing 3D printers in the production process.