Have Questions?

-

Only Top Quality Products

Only products from trusted brands

-

Personalized Services

We respond within 24 hours

-

Secure Payment

100% SSL Secure Payments

-

Canadawide Shipping

Free shipping on orders $99.99+

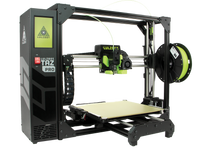

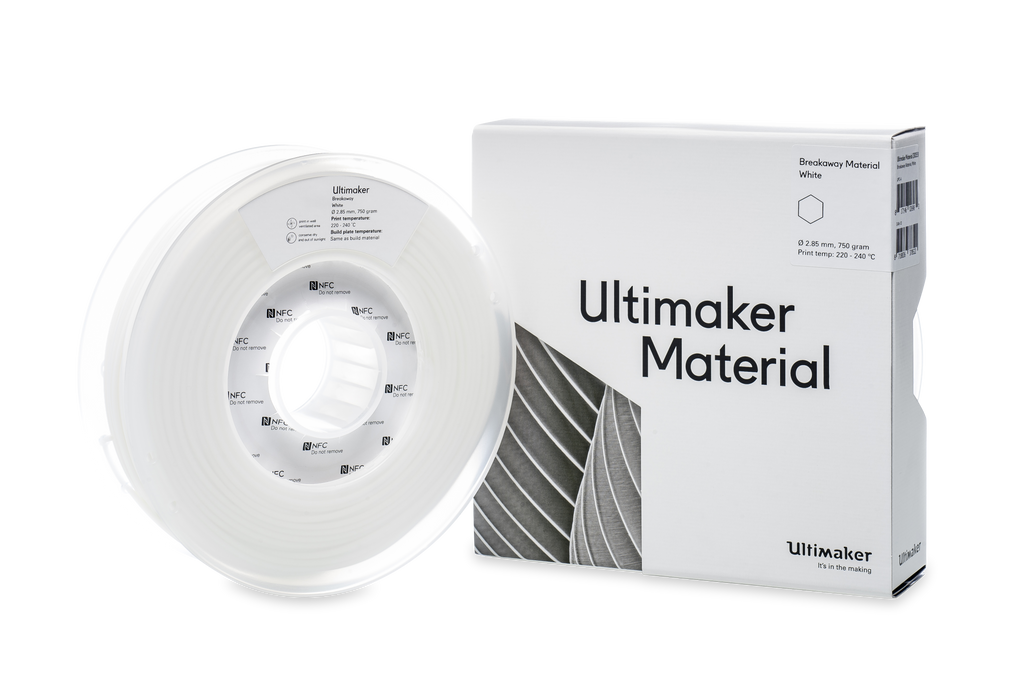

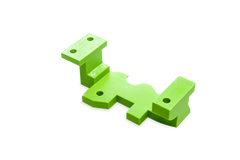

Ultimaker Breakaway is perfectly formulated for use with your Ultimaker S-line 3D printer!

Ultimaker Breakaway is a support material for multi-extrusion 3D printing. Breakaway support is quick to remove and does not need further post-processing for a smooth finish on your 3D print. Designed for a hassle-free 3D printing experience, Breakaway provides good adhesion to ABS, PLA, Nylon, CPE, or CPE+.

Reasons to choose Ultimaker Breakaway

- No sanding or waiting for your support material to dissolve. Simply print and break it away

- Ensures a smooth surface finish on your model

- Great results when combined with ABS, PLA, Nylon, CPE, or CPE+

- Long shelf life and less moisture sensitive compared to water-soluble support material, such as PVA

-

Ideal for use with build materials that are sensitive to water

Design freedom with more materials

Breakaway is compatible with ABS, PLA, Nylon, CPE, and CPE+, so it’s ideal for prototyping in the material you want.

Time and cost effective

Quicker to remove and more affordable than other support materials, Breakaway is also easy to store so stays usable for longer.

Leaves behind a smooth finish

Breakaway material has been developed to give reliable adhesion to your build material but peel away for a smooth finish.

Removing Breakaway support

Step 1

Tear

Remove the majority of the inner support structure with a cutting plier.

Step 2

Peel

Grab and peel the Breakaway support from the build material.

Step 3

Pull

Remove the last traces with pliers or a tweezer.

Ultimaker Breakaway and Ultimaker S-line 3D printers

Ultimaker Breakaway saves you time when removing support material from your 3D print. No more waiting for PVA to dissolve, or rough surfaces from sanding away build material supports. Breakaway is fast to remove while ensuring a quality finish on your model.

Learn more about How to print with Ultimaker Breakaway.